The katana stands as one of history’s most famous – and quietly intimidating – weapons. It’s a masterfully crafted curved sword that not just reflects centuries of Japanese tradition but has also captivated martial arts enthusiasts and collectors alike for generations. If you’re one of them, then understanding what goes into these legendary blades will reveal the fascinating intersection of ancient artistry and modern science. While traditional samurai swords were made from tamahagane steel through laborious processes, contemporary Japanese swordsmithing has evolved to incorporate new metals and techniques. In this guide we’re going to explore the types of steel used in today’s katana swords – taking a closer look at how traditional craftsmanship blends with modern materials to create beautiful, functional works of art.

The Legacy Of Traditional Japanese Swordsmithing

Japanese swords carry a cultural significance that goes way beyond being just a weapon. The katana, with it’s distinctive curved blade and circular or square guard, represents a historical narrative combining fire, steel, and centuries-old practices passed down through generations of master swordsmiths.

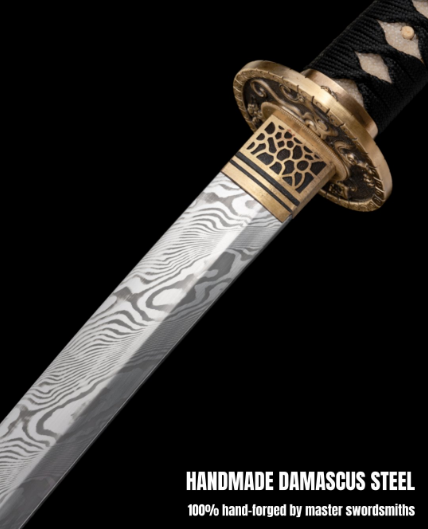

Traditional nihonto (real Japanese swords) were crafted from tamahagane, a type of steel made from specialized smelting processes. This iron sand-based material was folded over and over – sometimes hundreds of times – to remove impurities and create layered steel with exceptional strength and flexibility. The forging process involved getting the temperature just right, hammering it into shape and then quenching it in water or oil to get the blade’s properties just right. The visible hamon, or temper line, serves as a hallmark of authentic Japanese sword construction. This distinctive pattern appears along the blade’s edge where differential hardening created a harder cutting edge and more flexible spine. These traditional techniques required a level of skill and took months to complete a single blade, so you can see why nihonto are so highly prized.

Modern Steel Alloys in Contemporary Katanas

Swordsmiths and manufacturers today have adapted traditional methods to incorporate modern steel alloys, making quality katana swords more accessible while still maintaining that Japanese essence. Several types of steel have become standard in modern sword production.

High-Carbon Steel Variants

High-carbon steel is the most common choice for functional katana blades. These alloys contain anywhere between 0.45% to 0.95% carbon content, and the specific composition of each one will give you different characteristics.

1045 Carbon Steel – this steel has around 0.45% carbon and offers a good all-round durability with a moderate level of hardness. It’s a great introduction for martial arts beginners because it’s less brittle than higher-carbon options while still giving you a decent edge retention. A blade made from 1045 steel will hold up to practice cutting without the fragility worries of harder steels.

1060 Carbon Steel – this steel has 0.60% carbon and strikes a great balance between flexibility and edge-holding capability. Many practitioners prefer this steel for training because it offers sufficient hardness for cutting exercises but remains forgiving enough to handle the odd impact. That’s why 1060 steel is so popular among martial artists who practice tameshigiri (test cutting).

1095 Carbon Steel – this is the highest carbon content in this family – a whopping 0.95%! This steel achieves an exceptional level of hardness and can hold an incredibly sharp edge – it’s like having a traditional tamahagane in the modern world. However, the increased hardness does come with reduced flexibility, so you have to be a bit more careful handling and looking after it. Experienced collectors and martial artists often go for 1095 steel blades because they offer superior cutting performance.

Stainless Steel Options

Stainless steel katanas tend to be decorative, though some modern alloys have improved their functionality a bit. These blades have got chromium which gives them corrosion resistance but generally sacrifices some of the edge-holding properties found in carbon steel.

If you’re looking at stainless steel for display purposes or theatrical use, then that’s okay. These blades are low maintenance, will never rust and will look great even when exposed to moisture. But martial artists looking for a katana for actual cutting practice will want to opt for a carbon steel one, because stainless varieties tend to be lacking in hardness and edge geometry for traditional techniques.

Traditional Meets Modern: The Good, The Bad & The Trade-Offs

Understanding the difference between tamahagane and modern steel alloys will help collectors and practitioners make informed decisions when it comes to their samurai swords.

Durability And Performance: Modern high-carbon steels give you consistent quality and predictable performance characteristics. Unlike traditional tamahagane, which varied based on the iron sand source and smelting conditions, contemporary alloys give you standardized properties. A properly heat-treated 1095 carbon steel blade can match or even beat the cutting performance of historical katanas while maintaining better shock resistance.

Maintenance Requirements: Traditional nihonto and modern carbon steel blades both need regular care to prevent rust and keep their edge in check. Owners have to clean and oil their katana swords after each use, removing moisture and fingerprints that could lead to corrosion. Stainless steel options are a bit more low maintenance but they sacrifice the authentic feel and performance characteristics that serious collectors and martial artists are looking for